Services

We invent optimal solutions through nanotechnology

With state-of-the-art laboratories and the largest industrial production facility for nanofiber fabrics in Europe, we meet the needs of the most demanding clients.

Contract

development

Research reveals new ways

Using nanofibers, we develop hi-tech materials and fabric laminates in our state-of-the-art laboratory based on technical parameters of our clients. By combining our own know-how, years of experience and the latest trends, we create highly functional products that meet the highest technological standards and make life easier.

Experienced specialists from our development department oversee the progress and processing of each individual order to ensure the highest quality for our clients. Clients tell us their idea and refine the parameters, we fine-tune the details and then we find the best way to implement clients' visions. Thanks to many years of experience in the field, we also have extensive experience in converting production processes from a laboratory scale to an industrial line.

The initial development steps are on the NanospiderTM NS1WS500U.

- Laboratory machine Nanospider™ NS1WS500U for the production of fibers

This laboratory machine enables the preparation of nanofibers from a wide range of polymers, making various substrates with width of 300–500 mm. Compared to the industrial line, this alternative allows us to prepare samples ranging in centimeters to square meters, resulting in considerable material savings and minimization of operating costs.

Custom

made

We help achieving ambitious goals

Think big and bin the limits. Describe what features your material should have and we'll take care of the rest. Thanks to the large production capacity and innovative technologies we are able to realize even the most demanding tasks.

We are a certified workplace with the highest standards. Nanofibers are susceptible to a variety of parameters and therefore we optimize all process steps before industrial production, thus achieving the highest possible quality and minimizing production time and cost.

Analysis

We protect our know-how and experience

We support innovation and our understanding of nanofibers is exceptional. In our laboratories, we provide a complete production process from input material analysis to product quality assessment. Our equipment can also be used by external entities such as research organizations or industrial companies.

Nanofibers are very sensitive to process parameters and changes in environmental conditions. For all produced materials, strictly defined ranges of a number of observed properties are monitored by partial tests. The finished products are then rechecked to ensure maximum client satisfaction.

The following devices are used for research and innovation:

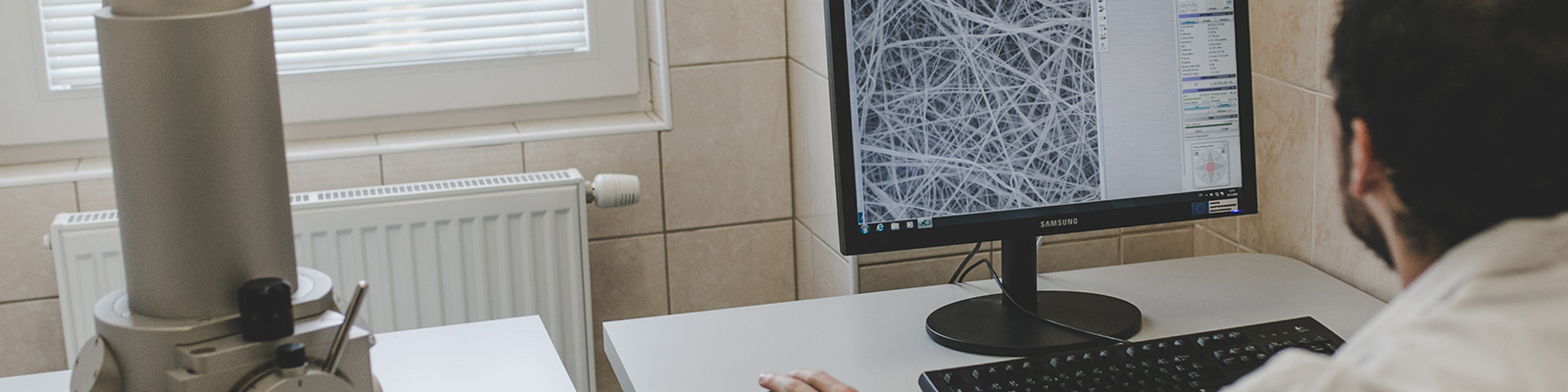

- Electron optic based microscope VEGA 3 SEM

We map the morphology of the structures and fiber diameters thoroughly using a scanning electron microscope.

- ARDMEL Hydrotester MK2

If necessary, we are able to measure the water penetration resistance of a material, commonly referred to as water column height.

- TEXTEST FX 3300

Breathability and pressure gradient, which are a key feature for a number of nanofibrous materials applications, are checked using the TEXTEST FX 3300.

- TOPAS PSM 165 FS

Using this instrument we measure the pore sizes of nanofibrous membranes.

- Automated filter tester TSI CertiTest® 8127

The CertiTest 8130 and Palas MFP 2000 TSIs allow the testing of material filtration efficiency based on standardized procedures (EN 143 and EN 779).

Expert-driven technology

When developing and manufacturing nanofibrous materials, we rely on state-of-the-art equipment to help us continuously improve our products and find innovative solutions. But technology is not the sole aspect. We would not have achieved our success without a team of experienced professionals.

Our mission

Tiny dimensions, Huge results

They are so small a naked human eye can hardly see them. Nanofibers are used in industry, healthcare, construction and many other areas. We thrive on utilizing their unique features to the full potential so that life can be a little easier for all of us.